Plastic formwork

Plastic formwork for foundations, columns, walls, and floor structures is undoubtedly a convenient, technological solution that reduces financial and time costs for construction. The advantages are obvious. Simple installation (one or two people are enough) and the absence of expensive lumber and work on its processing and installation.

Request advice from a specialist on the economic feasibility of using plastic formwork

More than 100 cycles of use, especially when layer-by-layer pouring with lightweight concrete (foam concrete), can significantly reduce costs without wasting time. The use of plastic formwork allows for a short time to carry out the pouring of the foundation, walls, or floor structures with concrete or foam concrete.

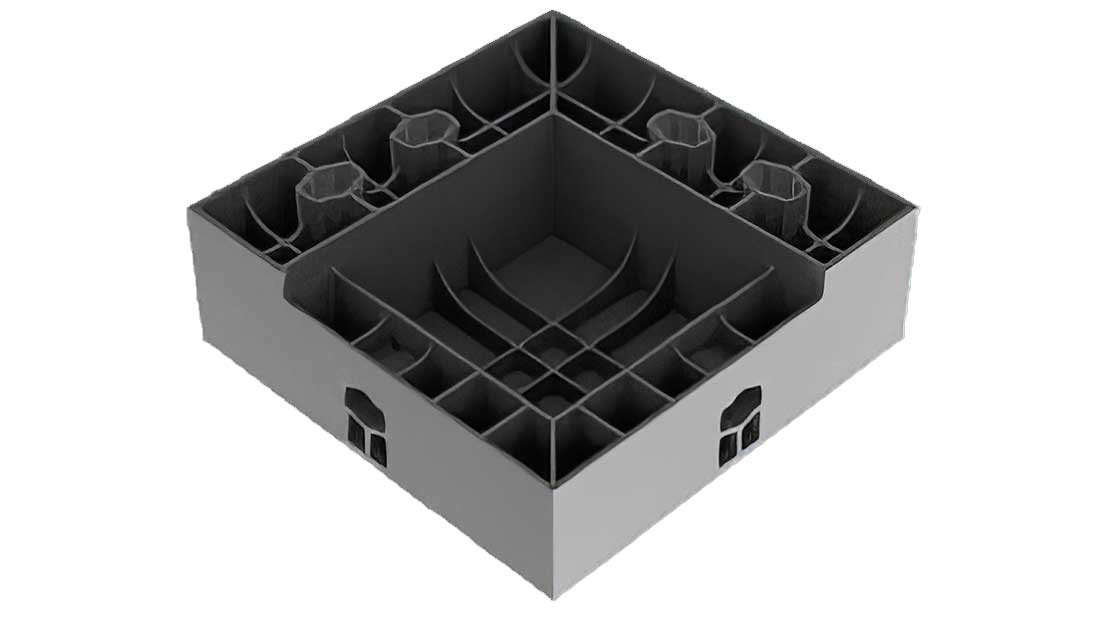

![[object Object]](../../../storage/photos/ef78652df19afe209e3ce9477cd68328.jpeg) Elements of plastic formwork used for the construction of foundations, walls and floor structures are panels of various sizes with technological holes for fastening to each other along the end plane and fixing the indentation between the working surfaces.

Elements of plastic formwork used for the construction of foundations, walls and floor structures are panels of various sizes with technological holes for fastening to each other along the end plane and fixing the indentation between the working surfaces.

Attention! The number and types of panels required for the implementation of tasks are identified on the basis of the size of the project. Before placing an order for formwork elements and components, you will need to provide our engineer with a project file for AutoCad or Revite.

The designer has provided situations in which there is a need to supplement the installed perimeter with small-sized panels. To get 70 cm, 30 and 40 cm panels are enough, and if it's necessary to fill 110 cm, an installation of two 40 mm and one 30 cm is used.

Elements of plastic formwork of the foundation, walls and ceilings/floor structures, 60 cm high:

| Width x Height x Depth | Kg | m2 | |

| 120 x 60 x 7.5 | 10.00 | 0.72 | Buy |

| 40 x 60 x 7.5 | 3.14 | 0.24 | Buy |

| 30 x 60 x 7.5 | 2.44 | 0.18 | Buy |

| 25 x 60 x 7.5 | 2.16 | 0.15 | Buy |

| 20 x 60 x 7.5 | 1.96 | 0.12 | Buy |

Elements of plastic formwork of the foundation, walls and ceilings/floor structures, 30 cm high:

| Width x Height x Depth | Kg | m2 | |

| 30 x 30 x 7.5 | 1.35 | 0.09 | Buy |

| 25 x 30 x 7.5 | 1.20 | 0.075 | Buy |

| 20 x 30 x 7.5 | 1.06 | 0.06 | Buy |

Elements of plastic formwork of the foundation, walls and ceilings/floor structures, 25 cm high:

| Width x Height x Depth | Kg | m2 | |

| 25 x 25 x 7.5 | 1.05 | - | Buy |

| 20 x 25 x 7.5 | 0.93 | - | Buy |

Elements of plastic formwork of the foundation, walls and ceilings/floor structures, 20 cm high:

| Width x Height x Depth | Kg | m2 | |

| 20 x 20 x 7.5 | 0.80 | - | Buy |

Assembly and fastening of plastic formwork elements

![[object Object]](../../../storage/photos/dfe217fa84a5a85575f86d414091a649.jpeg)

The fastening of the panels to each other along the end planes is ensured by using special plastic wrenches, the required number of which will need to be taken into account when placing an order for formwork elements.

Attention! Before placing an order for formwork elements and components, you will need to provide our engineer with a project file for AutoCad or Revite.

![[object Object]](../../../storage/photos/5005e7249ae95bb6aebb92ba3b3d5dc3.jpeg)

![[object Object]](../../../storage/photos/c8735d616c431d584a505bd4467124a4.jpeg) The fixation of the indentation between the working surfaces of the wall panels is ensured by special plastic spacer tubes of the required size with caps on the ends.

The fixation of the indentation between the working surfaces of the wall panels is ensured by special plastic spacer tubes of the required size with caps on the ends.

The tube can be picked up and cut into size independently, however the inner diameter should be taken into account when ordering the end element - a conical, plastic cap.

Spacer tubes

| Diameter | Thickness | |

| 18 | 1.5 mm | Buy |

| 20 | 1.5 mm | Buy |

| 22 | 1.5 mm | Buy |

| 18 | 2 mm | Buy |

| 20 | 2 mm | Buy |

| 22 | 2 mm | Buy |

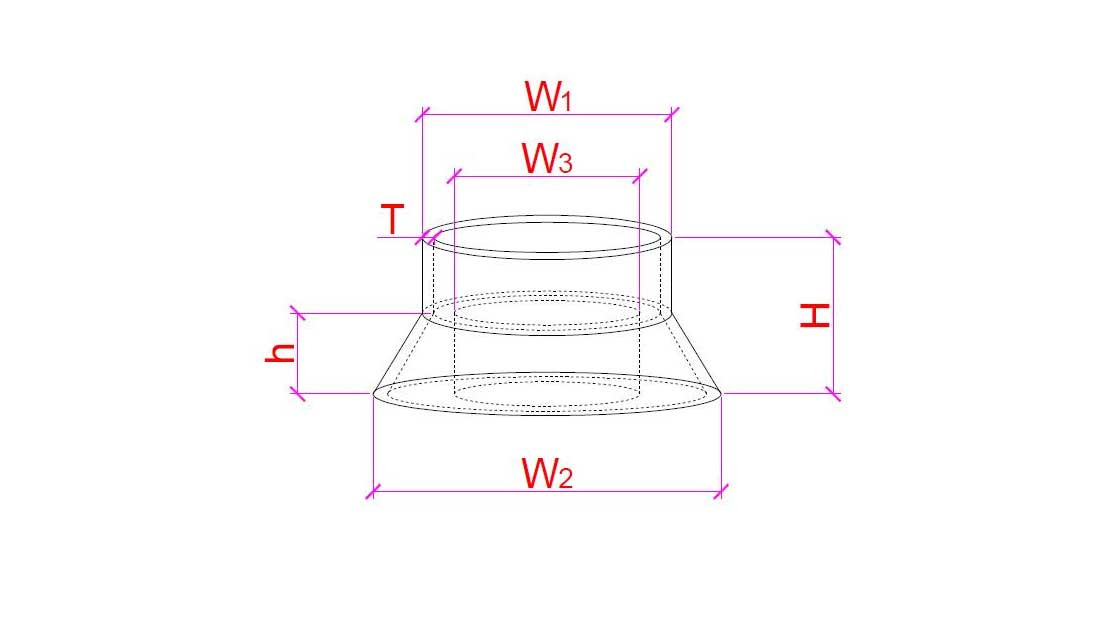

![[object Object]](../../../storage/photos/d453682de94b63114ed11e77a209ace8.jpeg) The end cone caps protect the surface of the plastic formwork shields from damage from contact with the spacer tubes. Caps are available in two versions - Female and Male with different mounting diameters (18, 20, 22, 25, 26 mm).

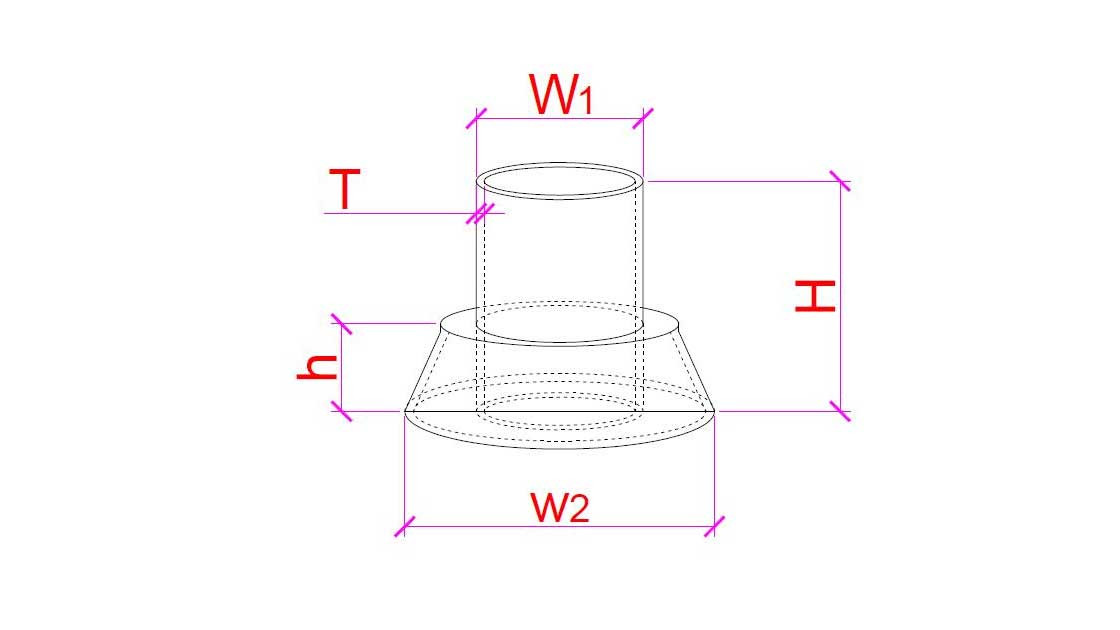

The end cone caps protect the surface of the plastic formwork shields from damage from contact with the spacer tubes. Caps are available in two versions - Female and Male with different mounting diameters (18, 20, 22, 25, 26 mm).

![[object Object]](../../../storage/photos/a4201bc831cb1b8e7adbd4ac21df75e7.jpeg)

The picture above shows a plastic end cone cap of the Female type for tubes fixing the indentation of plastic formwork shields.

![[object Object]](../../../storage/photos/7ced2da0e508b01d8b29d88dc43b0def.jpeg)

The picture above shows a plastic end conical cap type Male for tubes fixing the indentation of plastic formwork panels.

![[object Object]](../../../storage/photos/526a34e62ad82e3ee1206842f68a41fd.jpeg) Metal threaded tie bar and special nuts provide fixation of plastic formwork panels. As in the case of tubes and caps, studs are produced in different diameters: 12, 15 and 20 mm.

Metal threaded tie bar and special nuts provide fixation of plastic formwork panels. As in the case of tubes and caps, studs are produced in different diameters: 12, 15 and 20 mm.

(!) When ordering / buying nuts, we recommend you pay attention to the size of the stud it is designed for.

Threaded tie bar

| Diameter (mm) | |

| 12 | Buy |

| 15 | Buy |

| 20 | Buy |

Tie bar nut

| Diameter (mm) | |

| 12 | Buy |

| 15 | Buy |

| 20 | Buy |

![[object Object]](../../../storage/photos/0cca26b7d7577481608786cf740b32da.jpeg) In the picture above, you can see a corner element measuring 20 x 20 cm, which allows you to assemble the formwork for monolithic pouring of ceilings/floor structures.

In the picture above, you can see a corner element measuring 20 x 20 cm, which allows you to assemble the formwork for monolithic pouring of ceilings/floor structures.

![[object Object]](../../../storage/photos/b98352558d72e322ee1ac51324135fde.jpeg)

The picture above shows the elements of plastic formwork that allow you to form internal and external corners.

Elements of plastic formwork for the formation of external corners

| Width x Height x Depth | Kg | m2 |

|

| 25 x 60 (H) x 7.5 | 2.75 | - | Order |

Elements of plastic formwork for the formation of internal corners

| Width x Height x Depth | Kg | m2 | |

| 10 x 60 (H) x 25 | 2.76 | - | Order |

| 10 x 30 (H) x 25 | 1.50 | - | Order |

| 10 x 20 (H) x 25 | 1.10 | - | Order |

As mentioned above, the formwork can be assembled by one or two specialists. The panels are light, the procedure is similar to working with the Lego pieces - nothing complicated.

Calculation of the number of plastic formwork elements required for foundation pouring

When pouring the foundation with heavy concrete, horizontal or vertical "cold seams" are not desirable. For this reason, the number and composition of formwork elements required for pouring 100% of the concrete volume is determined.

Attention! Before placing an order for formwork elements and components, please send to our engineer a project file of your building in AutoCad or Revite.

Calculation of the number of plastic formwork elements required for foundation pouring

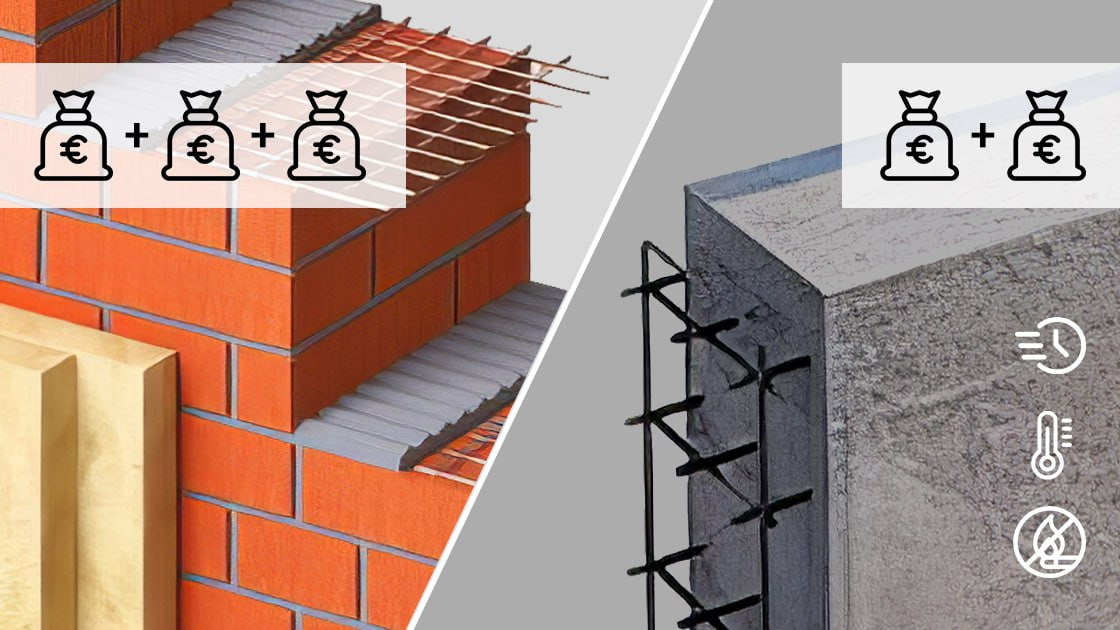

Heavy structural concretes

When pouring walls with heavy structural concretes, it is desirable to avoid vertical and horizontal cold seams. Cold seams are allowed subject to certain technologies, but companies selling formwork will charge you for full coating, which can be very expensive.

Lightweight cellular structural concrete (foam concrete)

We propose to consider the technology of pouring walls with reinforced foam concrete. This technology will allow pouring the structure in layers, no more than 0.6 meters in height per pouring, which will require significantly less plastic formwork. In addition to saving on formwork, you will get reliable, warm and fireproof walls with significant savings in time and money by eliminating the need for insulation and plastering from the procedure. Foam concrete is a great alternative to brick and other block materials!